Chinsun fiber cement board is the best choice for building board applications such as wall partitioning, wall cladding and decorative walling. Chinsun fiber cement board is suitable for residential, industrial and commercial buildings as well as schools and hospitals, especially where speedy construction, cleanliness and hygiene are of high importance.

Benefits of Chinsun Fiber Cement Board:

Standard References

| Standard | Category | Title |

|---|---|---|

| EN | 12476: 2012 | Fiber-cement flat sheet-Product specification |

| AS/NZS | 2908.2: 2000 | Cellulose Cement Product Part2: Flat sheets |

| ISO | 9001: 2008 | Fibre-Cement Flat sheets |

| BS | 476 | Fire tests on building materials and structuers-Part 20 |

| EN | 13501-1: 2007+A1: 2010 | Fire classification of construction products |

| EN | 1176/1182 | Fibre-Cement Flat sheets |

| CE | 12476:2012 | Fibre-Cement Flat sheets |

Building Material Class

| Size (mm) | Thickness (mm) | Weight (KG) | Edge Profile | Application |

|---|---|---|---|---|

|

1200 x 2400

1220 x 2440

|

4 |

18.00

18.61

|

Square-cut edge | Internal cladding |

|

1200 x 2400

1220 x 2440

|

6 |

27.00

27.91

|

Square-cut edge/

Recessed edge

|

Internal/external ceiling |

|

1200 x 2400

1220 x 2440

|

8 |

36.00

37.21

|

Square-cut edge/

Recessed edge

|

Internal partition

External wall cladding Wet area and tile backing

Floor underlay

|

|

1200 x 2400

1220 x 2440

|

9,10 |

40.50

41.86

45.00

46.51

|

Square-cut edge |

External wall cladding

Wet area and tile backing

Floor underlay

|

|

1200 x 2400

1220 x 2440

|

12 |

54.00

55.82

|

Square-cut edge/

Recessed edge

|

External wall cladding

Wet area and tile backing Floor underlay |

|

1200 x 2400

1220 x 2440

|

15 |

66.27

68.50

|

Square-cut edge |

Internal partitions with special requirements

Elevated Floor

|

|

1200 x 2400

1220 x 2440

|

18 |

79.52

82.20

|

Square-cut edge |

Internal partitions with special requirements

Elevated Floor

|

|

1200 x 2400

1220 x 2440

|

20 |

88.36

91.33

|

Square-cut edge |

Internal partitions with special requirements

Elevated Floor

|

Tools:

No special tools are required. The products can be used with normal nails, fastened by normal or self-drilling screws and cut by an electric power saw with a diamond blade.

Fixing:

Chinsun fiber cement board can be fixed to both timber (minimum size 1.5 x 3 inches) or steel frames (at least 0.55 mm thickness). The board must be supported at the edge at intermediate positions with centers not exceeding 600 mm. Screws must be located more than 12 mm from edges and 50 mm from board corners.

Fastener:

Fasteners can be both nails and screws. It can be nailed directly to timber supports with round wire nails. For metal screws, the size and length of the screw depends on the thickness of the board and the gauge of framing. Pre-drilling the board is a must unless self-embedding, self-drilling head screws.

Jointing:

Since fibre-cement board is subject to slight dimensional changes, a butt joint can be used in dry partitioning areas or where an exposed joint appearance is acceptable. For better water protection, either flexible acrylic or polyurethane based sealant can be used to seal gaps of 3-5mm.

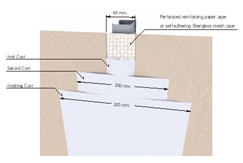

Flush Joint for ChinsunBoard, Recessed Edge

First coat: Fill the recessed area to the face of the sheet by using a jointing compound then embed the fibreglass mesh tape into the joint.

Second coat: Apply second coat at 200 mm width. Allow it to dry thoroughly before applying a finishing coat.

Finishing coat: Apply third coat at 300 mm width. Allow it to dry completely before sanding.

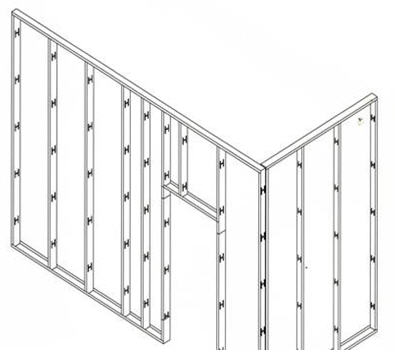

Recommended Frame Specification – For Internal Partition

Galvanized steel frame No.24 (0.55 BMT) is recommended to be used as stud for internal partition using ChinsunBoard. Stud shall be fixed at the spacing of 600 x 2.400 mm. Details of ideal stud size are shown as follows.

Technical Data

| Physical Properties |

|

|---|---|

| Thickness Tolerance | + 3% |

| Density | 1400-1700kg/m3 |

| Modulus of Rupture | > 10 MPa (Wet) |

| Modulus of Elasticity | 6000 + 50 MPa (Wet) |

| Water Absorption | < 35% |

| Moisture Content | < 12% |

| Water Tightness | Pass |

| PH Value | 7-8 |

| Thermal Conductivity | 0.15 W/m.K |

| Acoustic Insulation |

STC = 30 dB (6 mm single board) STC = 50 - 60 dB (10 mm composite wall) |

| Moisture Movement |

+ 0.4% |

| Fire Resistance Properties |

|

| Ignitibility | Pass |

| Fire Propagaton Index | I = 0.1 |

| Surface Spread of Flame | Class 1 |

| Reaction to Fire Classification | A1 |

| Durability Properties |

|

| Freeze / Thaw Resistance | Pass |

| Warm Water Resistance | Pass |

| Heat / Rain Resistance | Pass |

| Soak / Dry Resistance | Pass |

Transportation, Handing and Storage:

Deliver ChinsunBoard to the project site in the original, unopened package and store them in fully enclosed space where they will be protected against damage from humidity, direct sunlight, surface contamination and other causes of damage. Handle ChinsunBoard carefully to avoid chipping the edges or damaging units in any way. Handling and storage practices should follow the manufacturer’s recommended suggestions at all times.

Stack boards on a pallet.

Cover with a tarpaulin or other waterproof sheeting.

Carry the boards as shown in order to avoid damage/breakage or injury.